Foreword: Time flies. Looking back on this year, there were laughter, tears, sweat and the joy of harvest. Every experience is precious. Standing at the starting point of the new year, we carefully sort out the successes and failures of the past year, review those precious experiences and unforgettable lessons one by one, so that they can become valuable assets for us to move forward. And looking forward to 2025, we should embrace enthusiasm and longing, and march towards the new journey with determined steps, striving to make every stroke and every shade of color paint a wonderful chapter that belongs to us.

In today's highly competitive business environment, quality is undoubtedly the core element for enterprises to gain a foothold in the market and achieve sustainable development. Only by continuously improving quality can enterprises remain invincible in the fierce market competition and realize sustainable development. Since its establishment, YINUOLINK has always adhered to the product concept of "Product is King, Quality is Supreme". This concept is deeply rooted in the development context of the enterprise. In every segment, from the conception stage of product research and development, to raw material procurement, production and manufacturing, quality inspection, and then to after-sales service, quality is regarded as the top priority.

In 2024, based on the precise insight into market trends and the profound understanding of the enterprise's own development needs, YINUOLINK vigorously optimized the quality framework centering on the core goal of the "Quality Strategy". The aim is to control product quality from the source, improve the quality inspection segments in the production process, enhance employees' quality awareness, and ensure that every segment meets the high standard quality requirements.

Improve the R & D System and Consolidate the Guarantee of Product Quality

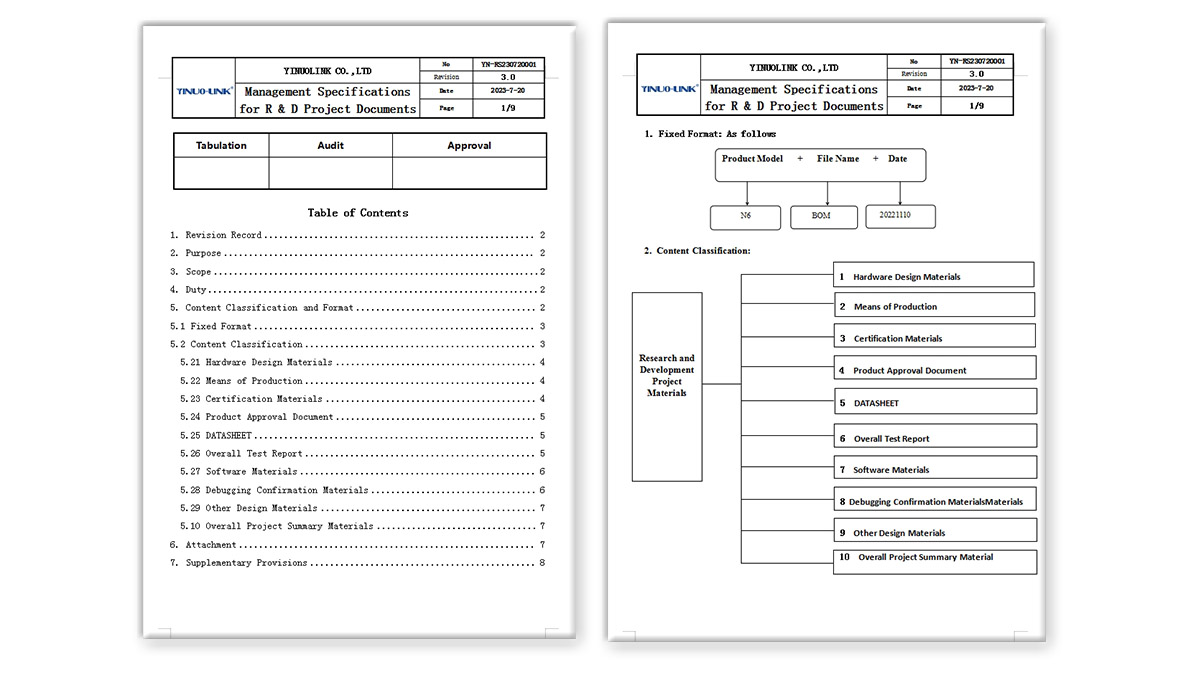

To enhance the efficiency and quality of product research and development, we have carried out a series of important improvement works. Not only have we improved the "Research and Development Process and Management System" for the entire process from the establishment of the research and development project to its conclusion, but also refined and standardized each item therein. This system clearly and in detail specifies the job responsibilities and work processes of R&D team, covering multiple key segments, including "Project Establishment Data", "Feasibility Analysis Report", various "Confirmation Reports" for materials, etc. The clear definition of these segments ensures that every step of the research and development work has rules to follow, making the entire research and development process more standardized and orderly. It is particularly worth mentioning the research and development design review link. In this segment, professional R&D team conduct strict reviews of the product design plan from different perspectives. From whether the structural design of the product is reasonable and convenient for production and manufacturing, to whether the selection of electronic components meets the requirements of high quality and stability, as well as whether the logic of the software system is rigorous and has good compatibility, etc., no detail is overlooked. Once potential quality risks are detected, modifications and improvements are immediately carried out. Only when it meets the standards is it allowed to enter the next R&D stage. Through the implementation of this series of measures, unnecessary repetitive work has been effectively reduced, the costs caused by poor communication have been lowered, thereby shortening the R&D cycle of new products and achieving reasonable control of R&D costs.

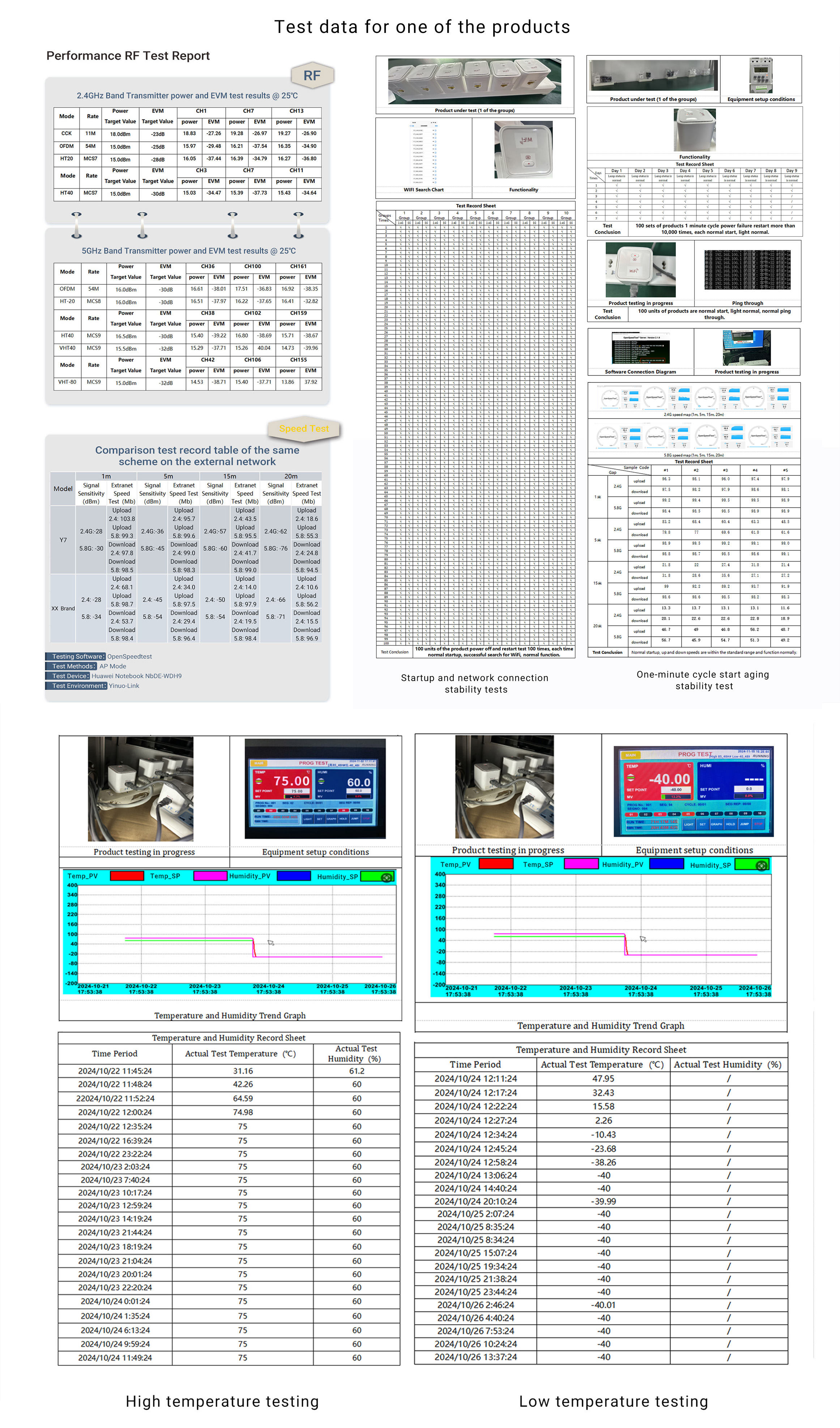

In the research and development test and verification segment, a series of multiple rounds and strict test processes such as functional tests, performance tests, reliability tests, and safety tests are the cornerstones to ensure that the product meets high quality standards. Among them, the functional test ensures that all functions of the product are in line with the original design and effectively meet the actual operational needs of users; the performance test conducts a comprehensive assessment of the comprehensive performance of the product, helping the product operate efficiently under multiple conditions and bringing users a smooth and unobstructed usage experience; the reliability test, as an important segment in product quality assurance, guarantees that the product can work stably in complex scenarios, which means that the product needs to remain stable under different environmental conditions, such as high temperature, high humidity, and long-term operation, minimizing the incidence of failures; the safety test comprehensively guards users' privacy and usage safety. Only samples that successfully pass all these test links are eligible to enter the small batch trial production stage.

Therefore, in order to pursue higher product quality and performance, the R&D department has further refined and deeply improved the original test project process. Precise and clear corresponding test conditions and test processes have been formulated for different types of products, such as the "RF Debugging Report", "Outdoor Open Distance Streaming Test", Covering various network links, "Throughput Test - Open Environment, Shielding Box Environment","Drop Test", "One-Minute Cycle Startup Aging Stability Test". For the Ethernet switch covering the test methods of using series or individual products under different voltages, "Power-off Restart Ping Packet and Real Network Test","Comparison Test of YINUOLINK's Products with Similar Products of Other Brands" covering multiple test methods such as LAN-WIFI/WIFI-WIFI,"Real Simulation Running Speed Measurement","4G/5G Real Network Speed Measurement","Software Test Cases", etc. It greatly contributes to improving the performance and stability of the products, and also accumulates extremely precious experience and provides highly valuable references for the subsequent product research and development. Meanwhile, for the comparison test projects, the "Selection Instructions for Product Performance Comparison Tests" was specially formulated, laying a solid foundation for the scientificity and standardization of the comparison tests in all aspects, from the selection criteria of the test objects, the clear definition of the comparison dimensions to the standardized setting of the test methods.

Furthermore, in order to test the performance of the products more comprehensively and deeply, several new test items such as "High and Low Temperature Test", "Waterproof Performance Test", "Startup and Network Connection Stability" have been added to conduct all-round inspections of the products from different dimensions, effectively improving the completeness and accuracy of the product performance test and providing a stronger guarantee for the quality and stability of the products.

To further enhance the working efficiency and technical level of the team, the R&D department has written a series of highly valuable operation guides and supporting videos, covering "Instructions for Using WiFi Test Instruments", "Instructions for Using QA Tools", "Use of High and Low Temperature Boxes", "Streaming Test", and "OpenSpeedTest Test", etc. Among them, the "Instructions for Using WiFi Test Instruments" elaborates in detail the basic principles of WiFi test instruments, helping team members understand the operating mechanism of the instruments from the bottom-level logic for more flexible application. At the same time, for possible faults, it provides detailed troubleshooting methods and solutions, providing strong support for quickly solving unexpected problems in the testing process; The "Instructions for Using QA Tools" elaborates on the core principles of product testing in detail. Its content not only involves key segments such as building the environment and debugging the software, but also introduces in detail the software and hardware testing processes and the specific usage steps of the testing tools, which helps the R&D team master the theories related to the testing steps more quickly and thereby improve the efficiency and quality of the testing work; The operation guide of "Use of High and Low Temperature Boxes" elaborates on the contents such as the startup of the equipment, parameter setting, operation monitoring and shutdown process, etc., helping R&D personnel precisely control the experimental environment, ensuring the accuracy and repeatability of the product reliability test, and effectively avoiding experimental deviations and equipment failures caused by improper operation; The operation guide of "Streaming Test" comprehensively elaborates on the principle, steps and data analysis methods of the streaming test; The operation guide of "OpenSpeedTest Test" introduces in detail the installation, configuration and usage steps of OpenSpeedTest, enabling accurate measurement of the network speed of the product in different network environments, timely discovery and resolution of network speed bottleneck problems, and ensuring that the product meets user requirements in terms of network performance.

With the continuous improvement, optimization and upgrading of the products, BOM changes are relatively frequent. This phenomenon has brought many challenges to the R&D and production processes, but at the same time, it also urges us to constantly explore more scientific and effective management methods. In order to better cope with this situation, the R&D team strictly distinguishes between the software and hardware sections to carry out the work. On the software side, a "Software Change Execution Form" has been newly added. This execution form records various information about software changes in detail, including the reasons for the change, the content of the change, the functional modules involved, the assessment of the impact scope of the change, etc. It can clearly sort out the process and details of software changes to ensure that the software change process is orderly. During the entire change management process, the R&D team strictly implements in accordance with the standards and specifications of the "BOM and ECN Change Workflow Management System". Whether it is a change in the hardware part or the software part, always ensure that the relevant technical documents are updated simultaneously with the BOM changes to avoid production errors. This is not only crucial for the production process but also helps enterprises accurately control the rhythm and quantity of material procurement, rationally plan the inventory level, effectively avoid the problem of sluggish material backlog caused by asynchronous information, and prevent the occurrence of out-of-stock phenomena. In addition, detailed change records provide detailed historical records for subsequent quality problem investigations, cost accounting, process improvements, etc., facilitating the tracing of the root causes of problems, summarizing experiences and lessons, continuously improving the management system, and improving the overall work efficiency and product quality.

Combine R & D with Production to Strengthen the Foundation of Production Quality and Efficiency

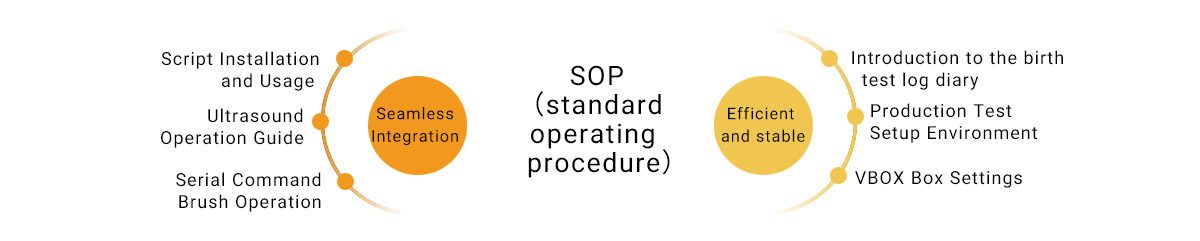

In order to effectively improve production efficiency and quality and ensure a close integration of R&D and production. The R&D team has formulated a series of detailed materials covering each key link of production testing.Among them, the production document "SOP (Standard Operating Procedure)" elaborates in detail the production steps and tools used for each product. It not only provides clear, accurate and unified operation guidelines for front-line production team, ensures stable product quality, reduces the defect rate caused by human differences, but also helps new employees quickly familiarize themselves with the work process and significantly improves the overall production efficiency. At the same time, it also provides a standardized and solid basis for the smooth transformation of R&D achievements into actual productivity, effectively promoting efficient communication and collaboration between R&D personnel and production personnel, enabling both sides to promptly detect and properly solve potential problems in the production process, achieving seamless docking between R&D and production, and promoting enterprises to produce high-quality products that meet market demands efficiently and stably; "The Introduction of Production Test Log Diary" elaborates, in clear steps, the meanings expressed by the content and information recorded related to the log during the product testing process; "Production Test Setup Environment" and "VBOX Settings" provide operators with detailed guidance on how to quickly and accurately set up the production test environment, covering everything from the connection of hardware devices to the configuration of software systems; "Screenplay Installation and Usage" elaborates in depth on the installation steps and practical application methods of various screenplay in production testing, helping employees improve the testing efficiency; "The Ultrasonic Operation Guide" details the operation procedures and precautions of the ultrasonic equipment in the production process; "Serial Port Command Flash Operation" provides detailed serial port command guidance for the flash operation to ensure the smooth progress of the flash process.

Meanwhile, in order to unify the product identification and ensure the standardization and traceability of the products, the R&D team jointly with the designers wrote the "Confirmation Letter of Product Nameplate Label and Shipping Mark Template", making clear and detailed regulations on the design, content, size, material and other aspects of the product nameplate label and shipping mark.