Foreword: In today's highly competitive business wave, the road ahead for enterprises is never smooth, challenges and difficulties follow. In this changing market environment, enterprises not only need to have the courage to take responsibility for the courage, but also have the boldness and perseverance to face the problem, accurate analysis of the root causes of the problem, breaking the waves forward. Only by having the courage to take on responsibilities and being united as one can they stand out in difficult situations.

In mid-December 2024, when YINUOLINK's test team was testing a product according to the regularized test procedure, one of the PCBA boards had a small probability of not starting. In this seemingly subtle anomaly, but like a calm lake under the dark surge, once left unchecked, it is very likely to trigger a greater crisis in the future, the product reputation, market share caused by the immeasurable impact. However, YINUOLINK's product concept of "Product is King, Quality is Supreme" and its work attitude of "Courage to Take Responsibility" have deeply influenced every YINUOLINK person. YINUOLINK did not choose to ignore or shirk but faced the problems directly and decidedly embarked on a difficult journey to overcome difficulties.

Once the problem was reported, it quickly attracted great attention from the R&D team. They knew that this was not only a simple technical fault, but also related to the company's reputation, customers' trust and the future fate of the product. From that moment on, the R&D team was like soldiers who heard the bugle call and did not hesitate to devote themselves to analyzing and solving the problem.

In the early stage of seeking the root cause of the problem, the R & D team was faced with numerous mysteries. Low probability events meant that it was extremely difficult to reproduce the faults. It was not like those common problems that had a clear troubleshooting path. Every test was like looking for a needle in a haystack, which might consume a lot of time and energy but achieve nothing. However, they did not flinch at all. Relying on profound professional knowledge and rich experience, they conducted meticulous investigations one by one from every chip, every circuit to every material of the hardware.

During this challenging process, in order to reproduce the problem, the test team and the R & D team worked closely and fought side by side. At first, it was found that one PCBA board showed a non-starting phenomenon. Then, investigation work was carried out around this situation in an effort to reproduce the problem so as to accurately locate the root cause. During the investigation process, it was found one after another that three PCBA boards also showed a certain non-starting phenomenon. In response to this overall situation, the R & D team gave full play to their expertise, worked closely with each other and exchanged ideas unreservedly. Sparks of wisdom continued to burst out in the frequent collisions of ideas. Based on in-depth discussions and accurate analysis, they quickly formulated many programs in a number of directions for investigation.

For the four “source of the problem” PCBA board, the team took the lead along the development of the first investigation direction of the multiple programs one by one to carry out the investigation, however, after the verification of the production test, the results are not as expected; But this didn't repel the R&D personnel at all. They adjusted their strategies decisively and launched multiple plans in the second direction without hesitation. However, the result was still not satisfactory. Even with repeated setbacks, the R&D team's unconquerable energy was thoroughly stimulated. Immediately after one after another direction of the different programs launched one after another, not afraid of cumbersome, with a high sense of responsibility and sense of mission, over and over again to carry out the test verification work. After tens of thousands of rigorous verification and no error, the direction of the anomaly was initially locked, and a solid and critical step was taken to overcome the problem completely.

After clarifying the direction of the anomalies, different schemes were adopted for each board to carry out material modification and 200 start-up tests were conducted for verification. In this process, it is necessary to execute each test session in a meticulous manner, rigorously recording the test data and the specific performance of the board under different test conditions. When one of the many programs in the test 200 times have successfully passed the verification, it will quickly and methodically 4 PCBA boards uniformly changed to have passed the best verification program for testing and verification again, such an operation process is not a one-time can be completed, you need to continue to cycle. Each cycle, it is necessary to analyze the test results with a more prudent attitude to find possible subtle problems, do not let go of any doubt, and so on and so forth until the four PCBA boards have successfully passed all the testing and verification process.

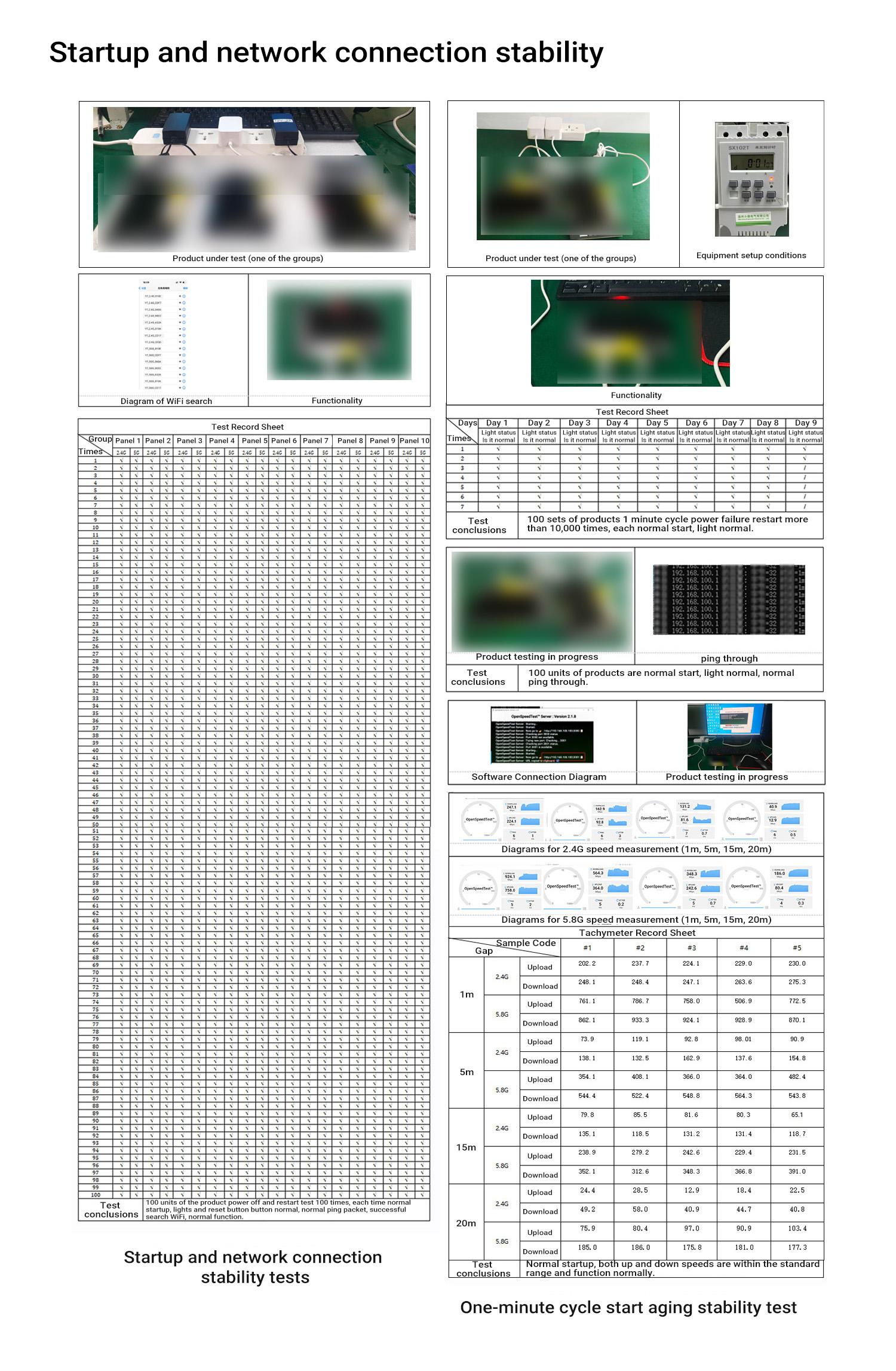

Subsequently, the team summarized all the relevant data and carefully selected the optimal scenarios. Each scenario has been validated with tens of thousands of test launches on 50 products. However, the test process was not all smooth sailing, and some problems were found one after another. But the team members always with strong faith, without the slightest flinch and wavering, sink their hearts, every single problem appeared in a cocoon like in-depth analysis, with solid professional knowledge and rich practical experience, one by one to find the crux of the problem, and with tenacious perseverance and exquisite technology to overcome the problem, to achieve breakthroughs. In this way, in the cycle of constantly finding problems, solving problems, and repeated tests, the whole team always upholds the attitude of excellence, not to miss any small points, even the most easily overlooked minor defects, but also carefully polished until the product reaches a near-perfect state, able to withstand the most stringent test of the market, and to present impeccable quality results for customers, and establish a solid reputation and a standard image in the industry.

Finally, after half a month of work, countless attempts and explorations, and tens of thousands of test experiments, the root cause of the problem was finally found. Not only that, in order to verify whether the problem has been thoroughly overcome at the root cause, a large scale test was subsequently carried out in multiple products of the same type of scheme, striving to examine the effectiveness and stability of the scheme in an all-round and multi-angle way. During the trial production of several hundred sets of multiple products, 200 start-up experiments were continuously conducted on each product, and all the products successfully passed the test verification.

This is a great test of physical strength, endurance and willpower, during which every failed test is like a stepping stone, an accumulation of one step closer to success; every subtle discovery is like a bright star, a motivation to inspire the team to continue to forge ahead. This arduous but glorious journey has witnessed the team's tenacity and persistence, and will undoubtedly leave a colorful mark in the long river of industry development.

After the problem was breakthrough and solved, YINUOLINK was not satisfied with the current phased achievements. On the contrary, the company, adhering to the spirit of craftsmanship of striving for excellence, reflected deeply on past experiences and lessons, and took prompt and decisive positive actions. The R&D team, like precision craftsmen, has carried out a meticulous reorganization of the whole process from the source of demand analysis to the product's glittering market launch. A series of more stringent evaluation nodes were added to minimize potential problems at the initial stage of product design. At the same time, the depth and breadth of the testing process was increased to ensure the quality and stability of the product; Not only that, YINUOLINK also focuses on the standardization and optimization of the entire life cycle of the product. From each screening process of carefully selecting raw materials, to the precise control of strict parameters in the production process, and then to the meticulous implementation of standards during the inspection of finished products, everything is clearly defined. This enables the product to have rules and regulations to follow in every link, every process, and every indicator, comprehensively filling the potential shortcomings that might have existed before, and meeting the strict market inspection in a perfect manner.

In this battle against the odds, YINUOLINK is not fighting alone, but with the support and cooperation of many forces behind it.In addition to the R&D team charging ahead, other departments are like closely meshed gears, operating in coordination and contributing their own strength to solve the problems. The test team, like sensitive quality inspectors, actively engaged in the huge testing work with a high degree of concentration and professionalism, not letting go of any minor flaw or potential problem. Through repeated tests and verification, they provided a solid guarantee for the quality of the product; The maintenance personnel are like highly skilled craftsmen, always on standby. Once it is found that the materials need to be modified or adjusted, they respond promptly and assist in the relevant operations with proficient techniques and rich experience to ensure that the materials can perfectly meet the demands of the product. The purchasers shoulder even more important missions. They not only have to ensure that the supply of materials can timely meet the progress requirements of R&D and production, but also strictly control the quality of the materials to prevent any quality problems from the source.

Besides, YINUOLINK would especially like to thank many partners for their strong support. They not only provided valuable opinions and suggestions in terms of technology and experience, helping YINUOLINK broaden the thinking for problem-solving; but also gave priority guarantee in the supply of raw materials to ensure that YINUOLINK would not be hindered by material shortages during the process of testing and improving products. This kind of cross-departmental and cross-enterprise collaborative cooperation fully demonstrates YINUOLINK's strong cohesion and centripetal force, making all employees think and work towards the same goal, and strive hard to achieve the enterprise's goals together. It also reflects the sound ecological environment of close connection, mutual assistance, and sharing weal and woe among all links in the entire industrial chain.

Looking back on this process, this is not just an ordinary technical breakthrough, but rather a vivid interpretation of YINUOLINK's corporate culture and spirit. The courage to take responsibility and not flinch in the face of problems; the daring to undertake means shouldering the solemn commitment to customers and the sacred responsibility to the market; unity as one, gathering the powerful force to overcome difficulties; the persistence in quality ensures that the product always remains outstanding.

From beginning to end, quality has always been the primary criterion that YINUOLINK adheres to, fulfilling the commitment to quality with practical actions, and allowing the concept of "Product is King, Quality is Supreme" to shine in every product. YINUOLINK continues to strengthen the quality management system, integrating quality control throughout the entire industrial chain, from the source to the terminal, injecting soul and quality guarantee into each product.

Looking forward to the future, YINUOLINK will carry this valuable experience and firm belief and continue to forge ahead bravely in the waves of the market. On the road ahead, perhaps there will be new challenges emerging, but YINUOLINK is always ready to meet every unknown challenge. YINUOLINK will keenly observe every subtle change in the market, taking innovation as the rudder to lead the way, quality as the sail to power the voyage, and the team as the oars to work together, writing its own wonderful chapter step by step with solid footprints.